Metech Welded Mesh Inc manufactures and exports high-security welded mesh fencing systems. Designed with close small opening and strong thick wire, HSF(high security fence) weld mesh is mainly used for power plants, governmental facilities, transportation hubs, residential communities and various premises.

Coils of clipped razor tape with medium barbs are commonly used in HSF system, with one row on top and one row on the bottom of the fence panels.

High-Security Welded Mesh Fencing Standard

Materials and construction of High-Security Fencing – Welded Mesh (HSF – WM) are in compliant with the following referenced standards:

- EN 10016-2: This standard outlines specifications for non-alloy steel rods suitable for drawing and/or cold rolling processes.

- EN 10218-2: This standard outlines the dimensions and tolerances for steel wire and related products.

- EN 10223-7: This standard outlines requirements for steel wire and wire products used in fences, with a particular focus on welded steel wire panels.

- EN 10244-2: This standard outlines non-ferrous metallic coatings on steel wire, specifically zinc or zinc alloy coatings.

- EN 10245-1: This standard outlines general rules for steel wire and wire products with organic coatings.

High Security Fence – Welded Mesh (HSF – WM) Panels

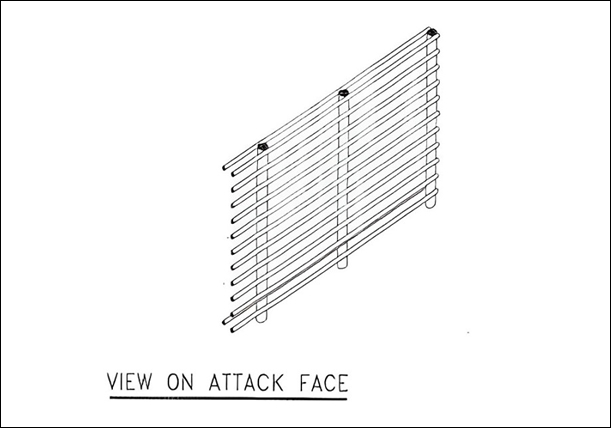

HSF – WM fencing panels are made of galvanized steel wires welded then coated with polyester at height of 2.42 meters. HSF Weld mesh panels feature round horizontal wires and thicker round vertical wires. Horizontal wires are doubled at every 1210 mm, a double wire at the bottom and a double wire at the top, as illustrated in Fig.

Fence Panel

Fence panels are galvanized and coated with polyester.

- Height of the Panel: Overall height 2416 + 3 mm.

- Width of the Panel: Overall width, not including overhangs, 2292 + 3 mm.

Mesh Dimensions and Tolerances

Nominal mesh size is determined by the distance between the centers of two adjacent wires:

- Distance between vertical wires: 76.2 + 2 mm

- Distance between horizontal wires: 12.7 + 1 mm

Wire Diameter

- Diameter of the horizontal wires: 4.00 + 0.08 mm

- Diameter of the vertical wires: 6.00 + 0.09 mm

Tensile Strength

- Horizontal wires: 600 to 810 N/mm².

- Vertical wires: 400 to 550 N/mm².

Wire Rod

Chemical composition of wire rod:

- Carbon (C): <0.10%

- Silicon (Si): <0.30%

- Manganese (Mn): <0.60%

- Phosphorus (P): <0.035%

- Sulfur (S): <0.035%

Wire rod conforms to the European standard EN 10016-2 and is designated as C9D.

Panel Installation

- Welded mesh panels are mounted with cover plate (20 x 5 x 2436 mm with pre-drilled slots) galvanized and polyester-coated, at a spacing of 330.2 mm.

- Fence panels are connected to the vertical posts with socket button head bolts M8 x 35/40, washers, and self-locking nuts made from stainless steel A2.

FENCE COATING

- Metallic Coating: The wires are galvanized with a minimum zinc weight of 275 g/m² for horizontal wires and 290 g/m² for vertical wires.

- Organic Coating: Mesh panels are coated with polyester after welding process, at average thickness 150 µm.

- Adhesion of Polyester Coating: Tested scratch about 50 mm long, and the coating should not lift more than 5 mm from the metal.

- Resistance to Salt Spray: For salt spray resistance, scratch the wire longitudinally to the metal for 50 mm. After testing under ISO 9227 for 1000 hours, there should be no under-film corrosion or adhesion loss greater than 10 mm, and no blistering, cracking, or crazing.

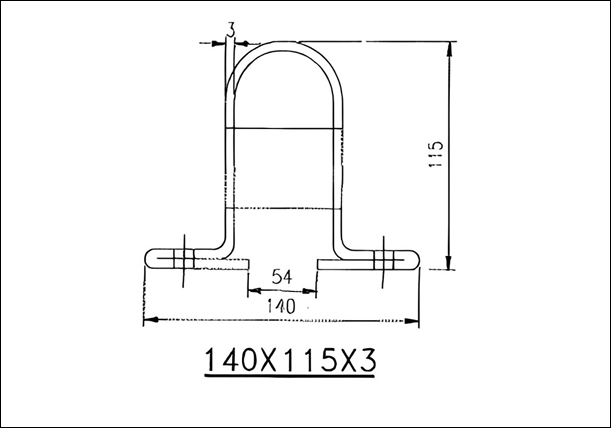

FENCE POST

- Posts are constructed from steel, hot-dip galvanized, and polyester-coated, with pre-drilled holes for assembly.

- Post size 140 x 115 x 3 mm, with welded steel foot plate at the bottom (refer to Fig.).

Post Materials

- Steel type for the posts is H380LAD Z 275 MAC, in accordance with EN 10292, with a minimum yield strength of 380 N/mm².

Steel Post Chemical Composition:

- Carbon (C): <0.10%

- Silicon (Si): <0.50%

- Manganese (Mn): <1.40%

- Phosphorus (P): <0.025%

- Sulfur (S): <0.025%

- Aluminum (Al): <0.015%

Spacing of Posts

- Standard post spacings are used throughout, except for gate posts.

POSTS COATING

- Metallic Coating: Posts are made from hot-dip galvanized steel, minimum zinc coating weight is 395 g/m², complying with ISO 1461.

- Organic Coating: After galvanizing, the posts are coated with polyester.

- Adhesion of Polyester: Test adhesion by making an X-cross scratch with a hard metal pointed engraving tool through the metal. Each scratch should be about 50 mm long. The coating should not lift more than 5 mm from the metal at any point along the scratch.

- Resistance to Salt Spray ISO 9227 standard: Test resistance by making an X-cross in the coating with a hard metal pointed engraving tool. Scratches should measure about 50 mm. After 1000 hours, no underfilm corrosion or loss of adhesion exceeding 10 mm from any scratch, and no signs of blistering, cracking, or crazing on the specimen.

FENCE FOUNDATIONS

Fence Post Foundations (HSF-WM):

- Fence posts with welded footplate, plate size min. 230 mm x 230 mm x 15 mm galvanized and polyester-coated.

- Posts secured with four anchor bolts at 16 mm diameter and 300 mm concrete penetration.

Concrete & Reinforcement for High Security Fence (HSF) Installation:

- Reinforced Concrete: Minimum strength of 30 N/mm² (K-300) at 28 days.

- Blinding/Plain Concrete: Minimum strength of 15.7 N/mm² (K-150).

- Reinforced Steel: Deformed bars conforming to ASTM A 615 / A 615M.

Foundation Trenches:

- Trenches level and compacted.

- Lay a 50 mm thick layer of blinding concrete with a 1000 mm polythene sheet before constructing the foundation beam.

Anchor Bolts:

- Four M16 anchor bolts with a locking nut, hot-dip galvanized.

Foot Plate:

- Footplate size 230 x 230 x 15 mm attached to the fence post.

- Minimum yield strength: 235 N/mm².

Site Preparation – Grading and Cleaning:

- Straight, flat, and level surface with thoroughly compacted soil or stone fill.

Razor Tape V Arm Support and Installation

Barbed Wire Extension Arm (‘V’ Shape):

- Constructed from steel hot-dip galvanized polyester-coated.

- L-profile dimensions: 50 x 50 x 5mm, length 540mm, with six notches for attaching six rows of barbed wire.

- Fitted atop fence posts, capable of supporting a minimum dead weight of 125 kg.

- Fixed securely to the post using mushroom head square neck bolts M8 x 30 with washers and self-locking nuts St. St A2 (two sets of two).

Welded Mesh (WM) Panel Erection:

- Installation of welded mesh panels and components must follow our recommendations.

- Allowed misalignment from top to bottom of welded mesh panels is one inch.

Concertina Barbed Wire and Razor Tape:

- Galvanized and polyester-coated concertina barbed wire and stainless steel clipped razor tape with medium barbs are used atop the fence panels.

- Corner posts and line posts with extension arms to support six horizontal strands of concertina barbed wire with short barbs. Coil of clipped razor barbed tape in diameter 965mm, attached to the face of the fence, barbed tape coil in diameter 620mm mounted on top of the fence.

CCTV and Detectors:

- HSF-WM system can have CCTV, motion detectors, and intrusion detection systems for maximum protection.