|

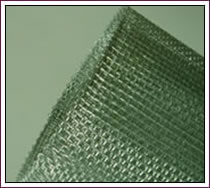

Metech supplies galvanized hardware cloth both woven type and welded type. The galvanizing of the meshes can be done before weaving or welding, or after the processing of weaving or welding. The latter processing enables thorough zinc plating to the hardware cloth and makes it stronger. A further vinyl or powder coating can be made to the hardware cloth at customers demand.

Galvanized hardware cloth woven mesh or welded mesh fabric can also divided into electro galvanized or HDG (hot-dipped galvanized) according to the treatment. Electro galvanized mesh hardware cloth is less cost compared with HDG one as the later used more zinc material in plating and it takes more time to work on it. HDG galvanizing has a thicker zinc coating and it offers good corrosion resistance, bright appearance, long service life and other features.

Metech welded mesh hardware cloth has two options: light and heavy type. The light type hardware cloth is mainly for tree fences while the heavy galvanized mesh is mainly for industrial screenings.

Coarse woven gal. hardware cloth is mainly used for window screen and door guards, machine screening, sand screens, etc.

|

|

| Black Vinyl Coating |

Powder Coated Welded Hardware Cloth |

| |

|

|

|

| HDG Galvanized After Woven Mesh, Plain Weave |

Gal. Steel Hardware Cloth Rolls |

Common sizes for Hot dipped GALVANIZED HARDWARE CLOTH MESH include 2mesh, 3mesh, 4mesh, 5mesh, 6mesh, 8mesh, 12mesh, etc. Wire gauge covers 16,17, 23, 24, 25, 26.

Welded Hardware Cloth:

Welded mesh hardware cloth can be made from a variety of materials, including carbon steel wire, stainless steel or plastic coated iron wire. Welded prior to galvanizing or after galvanizing.

Processing:

A wire mesh welded construction comprises an array of line wires, an array of cross wires overlying said array of line wires and a barrier material disposed between the array of line wires and the array of cross welded wires. The array of line wires is joined to said array of cross wires at the points of intersection and through the barrier material, thus securing the barrier material between the array of line wires and the array of cross wires.

Typical Sizes:

5/8" x 5/8", Wire Gauge 18,19,20,21;

3/4" x 3/4", Wire Gauge 16,17,18,19,20,21;

1" x 1/2", Wire Gauge 16,17,18,19,20,21;

1-1/2" x 1-1/2", Wire Gauge 14,15,16,17,18,19;

1" x 2", Wire Gauge 14,15,16;

2" x 2", 12,13,14,15,16

Standard roll length: 30m;width: 0.5m to 1.8m

Special sizes is available at request

Packing: The hardware cloth is wrapped in waterproof paper in rolls. Then in cartons or in pallet.

|

|

| Bright Zinc Plated Square Hole Welded Fabric |

Galvanized Mesh for Tree Fence |

Welded Mesh Hardware Cloth, Light Type

Light type welded mesh hardware cloth is mainly used as light fencing, wire basket, shelving and other processed wire products.

It can be divided into:

Hot Dipped Galvanized, Galvanized After Welding;

Galvanized;

PVC Coated.

Typical Sizes:

5/8" x 5/8", Wire Gauge 18,19,20,21;

3/4" x 3/4", Wire Gauge 16,17,18,19,20,21;

1" x 1/2", Wire Gauge 16,17,18,19,20,21;

1-1/2" x 1-1/2", Wire Gauge 14,15,16,17,18,19;

1" x 2", Wire Gauge 14,15,16;

2" x 2", 12,13,14,15,16

Standard roll length: 30m;width: 0.5m to 1.8m

Special sizes welded wire mesh is available at request

Packing: Welded mesh is wrapped in waterproof paper in rolls. Then in cartons or in pallet.

Heavy Welded Hardware Cloth

We produce welded wire cloth with extra big wire gauge, with special roll length or width (extra big or small).

Variety:

Welded wire hardware cloth with extra big roll width;

Hardware cloth with extra small roll width;

Welded With extra wire gauge.

Processing Varieties of Hardware Cloth:

Metech Hardware cloth has two types of processing basically: welded or woven. They can be further classified into galvanized before or after.

Processing types:

pre galvanized before welded;

hot dipped galvanised after welded;

pre galvanized then woven and galvanized after woven.

Pre-galvanized wire mesh is the most economical but is more prone to corrosion because the galvanized surface is burned off where the wires are welded.

However, pre-galvanized is more attractive in appearance than hot-dip galvanized. Galvanization process coats the wire with a zinc layer. Zinc coatings prevent corrosion of the protected metal by forming a physical barrier and by acting as a sacrificial anode if this barrier is damaged.

|